Summary

The project has two main components, namely, to establish a mechanics-based nonlinear model for representing joints in structural analyses, and a reliability framework at system level that considers randomness in the strength and behaviour of both members and joints. As its main aim, the project will pave the way for introducing the design-by-advanced-analysis method, also referred to as the Direct Design Method (DDM), in the structural engineering community, thus obviating the need for checking member and joint strengths to a structural standard. The direct design approach is more accurate, economical and faster than current design practice, provides more uniform structural system reliability, and encourages innovation in structural and architectural forms.

The focus of this project is on the behaviour, strength and variability of connections in structural frameworks and the influence of connection variability on the system strength and reliability.

This Project is supported by the ARC Discovery Project DP150104873.

Chief Investigators

- Prof Kim Rasmussen

- Associate Prof Hao Zhang

- Dr Shen Yan

- Prof Luis da Silva

PhD students and graduates:

- Dr Chen Zhu

- Dr Liusi Dai

- Dr Haoyu Liu

- Ms Luli Jiang

Project outcomes and significance

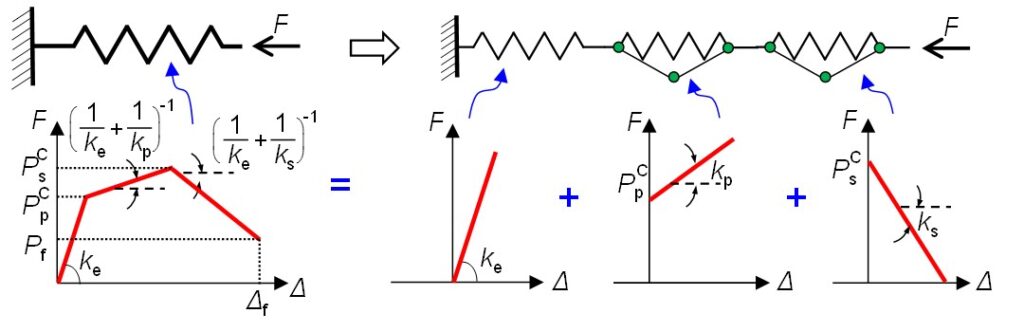

The Generalised Component Method has been developed as part of this project. The Method introduces tri-linear springs to extend the Component Method to the inelastic range and the post-ultimate softening range. By knowing the ultimate capacity of each component, and assembling all components in a representative model, it is possible to predict the ultimate capacity of the connection. A simple energy-based approach is added to model fracture and fracture propagation, thus also enabling in ductility of the connection to be predicted.

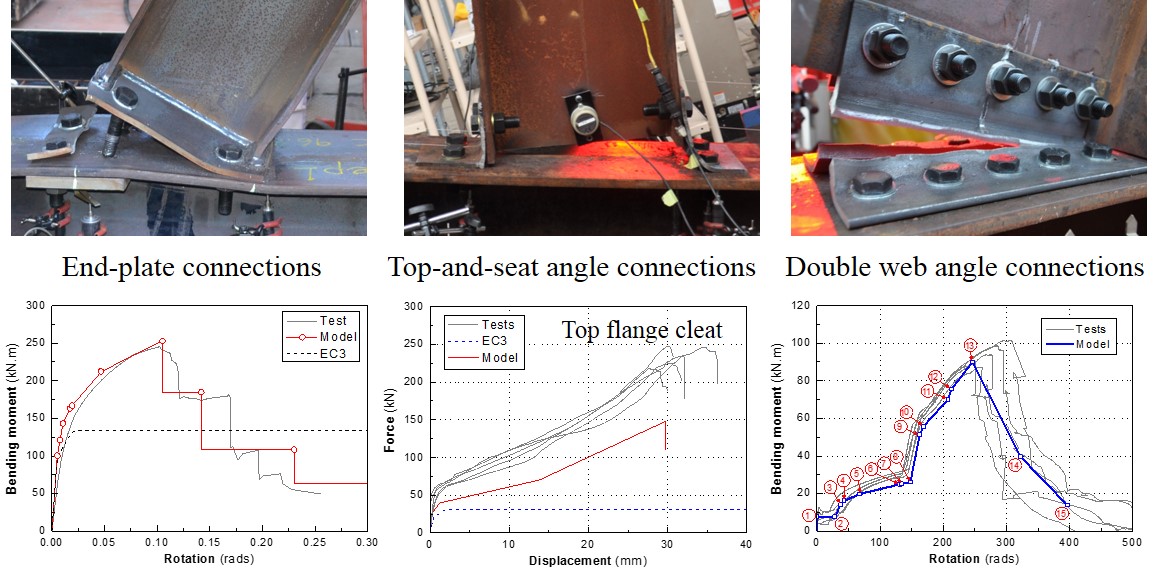

Full-scale tests were conducted on semi-rigid connections of varying stiffness, including bolted moment end-plate connections, top-and-seat angle connections and web side-plate connections. The tests were conducted to complete fracture to obtain the full-range experimental response of the connections. Multiple tests were conducted on nominally identical connections to obtain statistical data for the variability of the stiffness, strength and ductility of connections.

Finite element models have been calibrated against the connection tests over the complete nonlinear range modelling all connection components individually and accounting for contact between components and fracture. Excellent agreement been the finite element predictions and experimental observations are achieved over the complete loading range. The analysis results are proving the adequacy of current finite element software to accurately model the behaviour and strength of common types of steel structural connections.

A structural reliability framework has been developed that considers the variability of connections in addition to the variability of members and applied loads. Studies have been performed to calculate system resistance factors for various target system reliability indices for a range of configurations and types of semi-rigid connections of steel structural frameworks.

Ongoing work is focussed on incorporating full-range Generalised Component Method spring models into 3D finite element analysis of structural frameworks.

Publications

- H. Dai, H. Zhang and W. Wang, “A new maximum-entropy-based importance sampling for structural reliability analysis”, Structural Safety, 2016, Vol. 63, 71−80.

- G. Xue, H. Dai and H. Zhang, “A new unbiased metamodel method for efficient reliability analysis”, Structural Safety, 2017, Vol. 67, 1−10.

- L. Dai, X. Zhao and K.J.R. Rasmussen, “Flexural behaviour of steel storage rack beam-to-upright bolted connections”, Thin-Walled Structures, 2018, Vol. 124, 202-217.

- X. Zhao, L. Dai and K.J.R. Rasmussen, “Hysteretic behaviour of steel storage rack beam-to-upright boltless connections”, Journal of Constructional Steel Research, 2018, Vol. 144, 81-105.

- L. Dai, X. Zhao and K.J.R. Rasmussen, “Cyclic performance of steel storage rack beam-to-upright bolted connections”, Journal of Constructional Steel Research, 2018, Vol. 148, 28-48.

- H. Zhang, H. Liu, B.R. Ellingwood and K.J.R. Rasmussen, “System reliabilities of steel frames designed by the inelastic analysis and design method in AISC 360-10”, Journal of Structural Engineering, 2018, Vol. 144(3), 04018011.

- C. Zhu, K.J.R. Rasmussen and S. Yan, “Generalised Component Model for Structural Steel Joints”, Journal of Constructional Steel Research, 2019, Vol. 153, 330-342.

- C. Zhu, K.J.R. Rasmussen, S. Yan and H. Zhang, “Experimental full-range behaviour assessment of bolted moment end-plate connections”, Journal of Structural Engineering, 2019, Vol. 145, No. 8, 04019079.

- S. Yan, K.J.R. Rasmussen, X. Liu, L. Dai and X. Zhao, “Behaviour of H-section purlin connections in resisting progressive collapse of roofs”, Engineering Structures, 2019, Vol. 201, 109849.

- S. Yan, K.J.R. Rasmussen, L. Jiang, C. Zhu and H. Zhang, “Experimental evaluation of the full-range behaviour of steel beam-to-column connections”, Advanced Steel Construction, 2020, Vol. 16, No. 1, 77-84.

- S. Yan, L. Jiang and K.J.R. Rasmussen, “Full-range behaviour of double web angle connections”, Journal of Constructional Steel Research, 2020, Vol. 166, 105907.

- S. Yan, K.J.R. Rasmussen, L. Jiang, C. Zhu and H. Zhang, “Experimental evaluation of the full-range behaviour of steel beam-to-column connections”, International Journal of Advances in Steel Structures, 2020, Vol. 16(1), pp. 77-84, 10.18057/IJASC.2020.16.1.9.

- S. Yan, L. Jiang, K.J.R. Rasmussen and H. Zhang, “Full-range behaviour of top-and-seat angle connections”, Journal of Structural Engineering, American Society of Civil Engineers, 2021, doi.org/10.1061/(ASCE)ST.1943-541X.0002893.

- S. Yan and K.J.R. Rasmussen, “Generalised Component Method-based finite element analysis of steel frames”, Journal of Constructional Steel Research, 2021, Vol. 187, doi.org/10.1016/j.jcsr.2021.106949.

- W. Wan, S. Yan, H. Zhang and K.J.R. Rasmussen, “A generalised component method for bolted angle connections”, Journal of Constructional Steel Research, 2022, Vol. 198, doi.org/10.1016/j.jcsr.2022.107530.