Summary

Portal frames are widely used for industrial, rural and residential purposes to create large clear spaces. They are traditionally built from hot-rolled steel but in recent years, cold-formed steel solutions have emerged for short to medium spans up to about 15 m. The purpose of this project is to engineer competitive long-span cold-formed steel systems that enable portal frames with spans up to 35 m to be built. This will require innovative joints to be devised which eliminate slip and localised buckling, and maintain high stiffness at service and ultimate loads. It will also require advanced design methods to be developed which consider discrete restraints from purlins, girts, etc, by analysing the complete system using nonlinear methods.

This Project is supported by the ARC Linkage Project LP120200528. The industry partner is Bluescope Lysaght https://www.lysaght.com/, a subsidiary of Bluescope Steel.

Chief investigators

- Prof Kim Rasmussen

- Associate Prof Hao Zhang

PhD students and graduates:

- Dr Hannah Blum

- Dr Rinchen

Project outcomes and significance

The project comprised two major investigations on portal frames composed of back-to-back double C-sections and frames composed of single C-sections. Each investigation comprised a series of full-scale tests on complete portal frames and connections, detailed finite element modelling, analytical developments and procurement of new design guidelines for cold-formed steel portal frames.

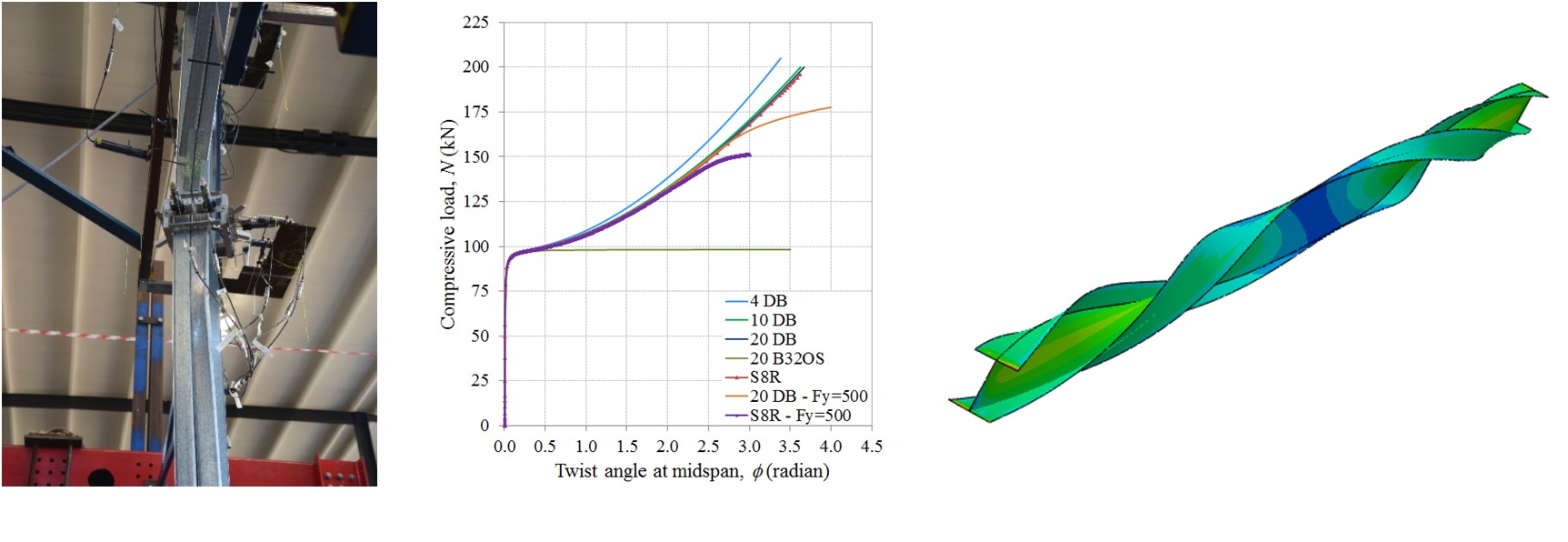

The full-scale tests were conducted on a two-bay system featuring three portal frames, purlins connecting the frames and cross-bracing in side panels to maintain stability in the lengthwise direction. The central frame was loaded using a dual-actuator arrangement for simulating gravity loads in combination with a horizontal load to simulate wind action. Of the three frames, only the centre frame was loaded. The side panels were left open to represent the critical design situation where unimpeded access to the internal area is provided from all sides, as is frequently required in agricultural applications. Failure occurred by flexural-torsional buckling of the unbraced columns when subjected to combined bending and compression by the adjoining rafters and eave joints. Alternatively, failure occurred in the eave joint in several configurations of double C-section frames.

Solutions were identified to enhance the stiffness and strength of the eave and apex connections. Design methods were also developed to account for the detrimental effect of bimoments introduced at the joints of single C-section frames through contact forces at bolts eccentric from the shear centre plane of the upright. Conventional design methods were shown to be optimistic unless bimoment effects are accounted for.

Fully nonlinear finite element models were calibrated against the tests using both beam and shell finite elements. Simplified system reliability analyses were conducted to determine the system resistance factor to use in applying the Direct Design Method to cold-formed steel portal frames. The system resistance factor was shown to be slightly lower than for typical hot-rolled steel frames.

A 7 degree of freedom beam finite element was also developed as part of the project, featuring warping deformation as one of the variables. The element was implemented in Opensees software and uses corotational formulation of this to track large displacements. Routines were written to enable both elastic and inelastic analyses.

Publications

- H.E. Blum and K.J.R. Rasmussen, “Elastic Buckling of Column with Discrete Elastic Torsional Restraint”, Thin-walled Structures, Vol. 129, 2018, pp. 502-511.

- H.E. Blum and K.J.R Rasmussen, “Experimental investigation of long-span cold-formed steel double channel portal frames”, Journal of Constructional Steel Research, Vol. 155, 2019, pp. 316–330.

- H.E. Blum and K.J.R. Rasmussen, “Experimental and numerical connection effect study of long-span cold-formed steel portal frames”, Journal of Constructional Steel Research, Vol. 155, 2019, pp. 480-491.

- Rinchen and K.J.R. Rasmussen, “Numerical modelling of cold-formed steel single C-section portal frames”, Journal of Constructional Steel Research, Vol. 158, 2019, pp. 143-155.

- Rinchen and K.J.R. Rasmussen, “Behaviour and modelling of connections in cold-formed steel single C-section portal frames”, Thin-walled Structures, Vol. 143, 2019, 1-16.

- Rinchen, K.J.R. Rasmussen and H. Zhang, “Design of cold-formed steel single C-section portal frames”, Journal of Constructional Steel Research, Vol. 162, 2019, 1-14.

- Rinchen and K.J.R. Rasmussen, “Experiments on long-span cold-formed steel single C-section portal frames”, Journal of Structural Engineering, American Society of Civil Engineers, Vol. 146(1), 2020, 1-16.

- Rinchen, G.J. Hancock and K.J.R. Rasmussen, “Geometric and material nonlinear analysis of thin-walled members with arbitrary open cross-section”, Thin-walled Structures, 2020, Vol. 153, 1-19.