Summary

The project aims to produce a design-by-analysis method for steel frameworks that explicitly models the complete set of failure modes including fracture of connections. The project will develop (i) models that can accurately predict the fracture behaviour of welded and bolted connections, and (ii) system reliability calibrations that account for random variations in the parameters controlling the strength of steel frameworks including fracture. The outcomes of this research will substantially advance the design of steel structures as it will become possible to analyse any type of structure for any type of failure including fracture. With the new design method there is no need for checking member and connection strengths to a national code.

This Project is supported by the ARC Discovery Project DP190103737.

Chief Investigators

- Prof Kim Rasmussen

- Associate Prof Hao Zhang

- Dr Mani Khezri

- Prof Greg Deierlein

- Dr Shen Yan

PhD students and graduates:

- Ms Xiaofan Liu

- Mr Jingsheng Zhou

- Mr Wodong Wan

Project outcomes and significance

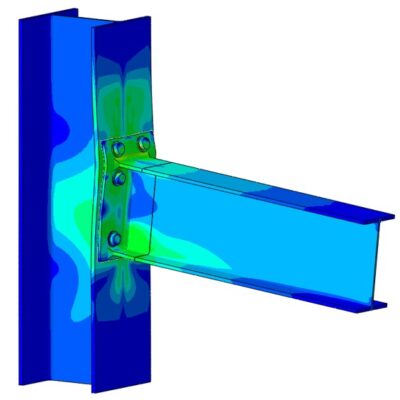

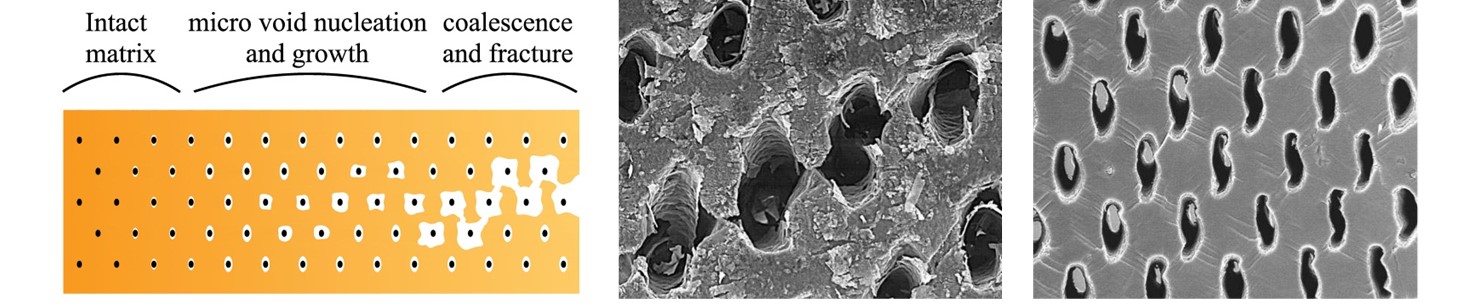

Models to simulate the initiation and propagation of fracture in steel structural connections are being investigated with application to welded and bolted connections. For welded connections, the main focus is on determining the fracture properties of the heat-affected zone (HAZ) as well as geometric irregularities near the HAZ. For bolted connections, the main focus is on the influence of friction and high contact stresses at the bolt and ply interface on fracture initiation.

Extensive series of tests are being performed on standard and miniature tensile and shear coupons to determine material properties including properties for damage-based models for ductile fracture initiation. Separate test series will be conducted on simple welded and bolted joints, carefully instrumented to measure crack initiation and propagation. As part of the experimental investigation, neutron diffraction measurements will be obtained at ANSTO to map the residual stress field at and around the HAZ.

Once fracture models have been calibrated against tests, Monte-Carlo simulations of steel structural frameworks will be conducted to obtain statistical data for the ultimate strength and ductility, accounting the variability of all main random variables including variables controlling fracture initiation and propagation. As the last step in this project the statistical data thus obtained will be incorporated in systems reliability analyses to determine systems resistance factors for given indices of reliability.

Publications

- X. Liu, S. Yan, K.J.R. Rasmussen and G.G. Deierlein, “Verification of void growth-based exponential damage function for ductile crack initiation over the full range of stress triaxialities”, Engineering Fracture Mechanics, 2022, Vol. 269, doi.org/10.1016/j.engfracmech.2022.108571.

- X. Liu, S. Yan, K.J.R. Rasmussen and G.G. Deierlein, “Experimental investigation of the effect of the Lode angle on fracture initiation of steels”, Engineering Fracture Mechanics, 2022, Vol. 271, doi.org/10.1016/j.engfracmech.2022.108637.